STLP300 Feed Pellet Plant

STLP300 Feed Pellet Plant

STLP400 Feed Pellet Plant

STLP400 Feed Pellet Plant

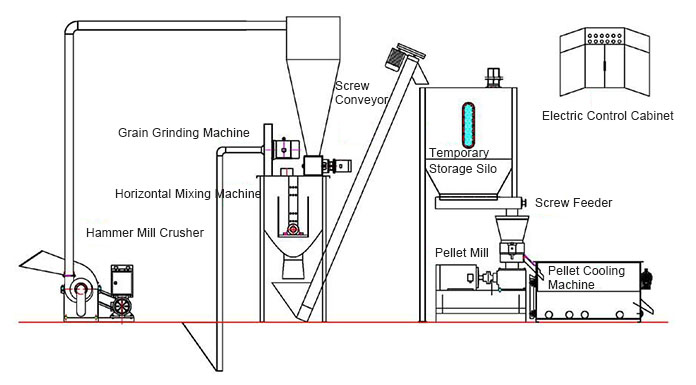

STLP300/STLP400 small feed pellet plant is a small scale pellet feed plant that produces 600-800kg/h and 800-1000kg/h animal feed pellets, widely used to produce feed pellets for cattle, cow, sheep, goat, horse, chicken, broiler, duck, goose, bird, fish (sinking fish feed pellets), and so on. It is mainly composed of small hammer mill, small feed mixing machine, screw conveyor, storage silo, and small feed pellet mill, feed pellet cooler, feed pellets packaging machine, etc. All machines in this small animal feed pellet plant are optional as to your specific needs and requirement.

| Model | Power(kw) | Capacity(kg/h) | Weight(kg) | Dimension(mm)L*W*H |

|---|---|---|---|---|

| STLP300 | 38.4 | 600-800 | 1700 | 7340*2360*4000 |

| STLP400 | 56.1 | 800-1000 | 2100 | 7445*2945*4000 |

| Note: The above parameters are WITHOUT the optional Bucket Conveyor & Packaging Machine. If you need these 2 machines, leave us a message>> | ||||

As shown in the Figure, feed the oil cake & other hard /heavy/oversized materials from hoper and they will be processed by Hammer Mill Crusher to ensure their size small enough to mix with other materials. The maize (store & directly feed from ground) is sucked into the Grain Grinding Machine and crushed into fine powder. Any other powder/soft materials, such as wheat bran, bone meal, microelement, vitamin, etc, which don’t need to be crushed, they can directly feed into the horizontal mixing machine through the pipeline of grain grinding machine. All powder mix uniformly in Horizontal Mixing Machine. Then the mixed materials is discharged into the hopper of Screw Conveyor, feed into Temporary Storage Silo. By Screw Feeder, the mixed materials are uniformly and continuously feed into the Pellet Mill then produced into feed pellets. The pellets are discharged into Pellet Cooling Machine. With the cooling process, the fresh & hot pellets are cooled, the pellet temperature is not more 5℃ than the room temperature. The cooled pellets are ready for packing.

It can crush a wide range of feed raw materials, like hard, heavy or oversized farming materials, such as soybean (soya bean) oil meal, straw, stalk, alfalfa, dry/fress grass, and so on. The raw materials will be crushed into diameter about 3-5mm, which is suitable for following mixing and pelletizing steps. More about hammer mill>>

Both horizontal and vertical mixing machines are suitable for feed raw materials mixing. The feed mixer can mix all the materials together uniformly, so it is the key euipment to guarantee feed pellets quality. It is easy to operate, occupies small area and consumes low electricity. More about feed mixer>>

In STLP300/400 small feed pellet plant, the ZLSP300/400 feed pellet mill is adopted. This feed pellet mill is widely used in small and medium scale feed pellet production pkant, livestock, poultry, fish farms and also for individuals. The 3 rollers design greatly improves the working efficiency of this feed pellet plant. Besides, all parts of this small feed pellet mill are made from high quality materials to prolong its service life. More about small feed pellet mill>>

LQS Series feed pellet cooler is to cool down the fresh-made hot feed pellets from the pellet mill. When the feed pellets just made out, they have a temperature of 70-85℃, so they must be cooled down to room temperature to meet storage requirement and in case of mildew.More about feed pellet cooler>>

It is a piece of necessary equipment for clients who make feed pellets for sale. The packaging bag capacity can be chosen by clients.

More about feed pellet packaging machine>>

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!