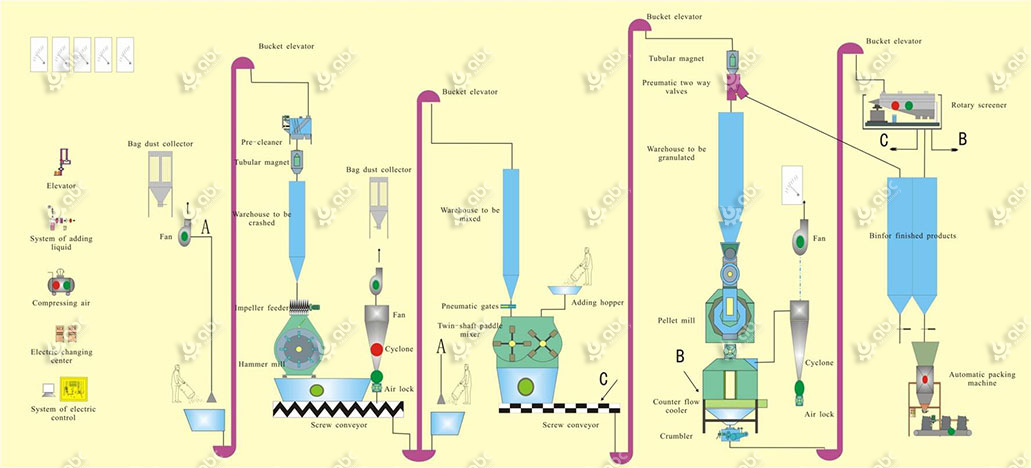

The medium capacity animal feed pellet production line here refers to the 1-15TPH Feed Pellet Line. It is usually built for small or medium scale animal feed production factories. The medium feed pellet line can process feed pellets for poultry, livestock and also fish (aquatic feed). The main machines in this kind of pellet production line include: feed hammer mill, silo, mixing machine, ring die feed pellet mill, feed pellet cooling machine, feed pellets packaging machine, etc.

With years of experience in feed processing machinery R&D, ABC Machinery have more than 10 engineers in making business plans of feed pellet production lines for clients from domestic and abroad.

| Capacity | Pellet Mill Model |

|---|---|

| 1~2t/h | BPM25 |

| 3-5t/h | BPM32 |

| 3-7t/h | BPM35 |

| 4-10t/h | BPM40 |

| 6-15t/h | BPM45 |

It adopts waterdrop shape crushing chamber, Ultra wide crushing chamber and outlet, "U" type twice strike design, anti circulation design, movable full open door, etc. Chain linkage type pressure screening mechanism is easy to operate. More about feed crushing machine>>

There are 2 types of feed mixers for complete feed pellet line: horizontal ribbon mixer and double-shaft paddle batch mixer. The first one is most commonly used and saves energy; the latter one can add liquids. More about feed mixing machine>>

It is equipped with stainless steel feeder and Denmark original imported Danfoss inverter contorl, automatic grease adding system. You can choose single-conditioner feed pellet mill and double-conditioner feed pellet mill. More about ring die feed pellet mill>>

It adopts a new octagonal cooling chamber without cooling dead angle. Countercurrent design can prevent hot pellets from directly contacting with cold air and cause fracture. Crumbler is installed in the lower part of the cooler More about feed pellet cooling machine>>

It is used to crumble large diameter feed pellets into small particles, in order to meet small animal feeding, such as for chicks. By this method, the whole feed pellets production cost can be decreased, and it is much easier than directly manufacturing small size feed pellets.

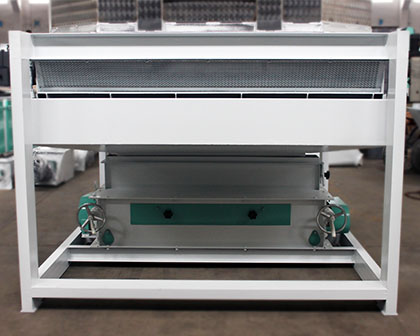

This machine aims at grading the pellets after cooling and crumbing, so that feed pellets that meet standards can go to following packaging procedure, while large pellets or powder will go back to pelletizing or crumbling processes.

There are automatic packaging machine and manual packaging machine for you to choose. It is usually composed by measurement scale, bag-sewing machine and conveyer belt, etc.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!