Ring die animal feed pellet mill in feed processing industry is used to press powdery feed raw materials into feed pellets (cylindrical granules) through the ring die holes under water and heat conditioning.

What feed pellets can it process?

cattle, sheep, cow, goat, chicken, horse, rabbit, and many other livestock feed pellets or poultry feed pellets.

The purpopse of using poultry feed pellet mill

- Making feed raw materials into pellets can prevent animals from being picky eaters, which makes sure all animals have comprehensive nutrition;

- Feed can have a higher rate of return;

- Volume of feed is greatly decreased, which makes feed storage and transport more economical;

- Can also kill the salmonella in feeds,

- Can prevent feed components from grading automatically to decrease environmental pollution.

Cattle feed pellet mill technical parameters

| Model | BPM25 | BPM32 | BPM35 | BPM40 | BPM45 |

|---|---|---|---|---|---|

| Main motor power | 22kw | 22kw×2 | 30kw×2 | 45kw×2 | 55kw×2 |

| Capacity (t/h) | 1-2 | 2-5 | 3-7 | 4-10 | 6-15 |

| Ring die inner diameter (mm) | 250 | 320 | 350 | 400 | 450 |

| Feeder power (kw) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 |

| Conditioner motor power (kw) | 1.1 | 2.2 | 2.2 | 4 | 4 |

| Size (mm) | 1750× 650× 1750 | 1900× 1800× 1650 | 2100× 2000× 1850 | 2200× 2000×2150 | 2300× 2350× 2150 |

| Weight (kg) | 800 | 2000 | 2400 | 2900 | 3500 |

For small capacity 90-1000kg/h, see small animal feed pellet machine>>

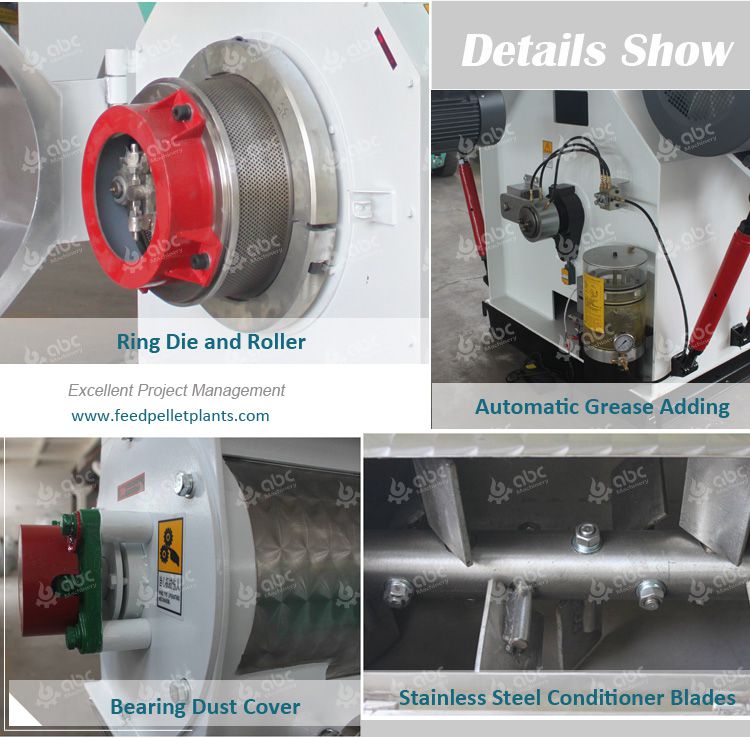

Features of large feed pellet mill for sale

- The feed pellet mill is equipped with stainless steel feeder and Denmark original imported Danfoss inverter contorl to guarantee accurate and reliable material feeding.

- It adopts fully stainless steel conditioner and large open access door for convenient maintenance. Inside the conditioner, there are Food Grade 304 Stainless Steel paddles and paddle shaft, which can guarantee the safety of livestock and poultry feed pellets. There are single-conditioner feed pellet mill and double-conditioner feed pellet mill. Single conditioner type is usually for making poultry feed pellets, while double-conditioner type can make better pellets (but the price is also higher).

- Stainless steel feeding pipe, door cover and scaleboard, which are beautiful and anti-corrosion.

- Ring die feed pellet mills adopt dual-motor V-belt drive system to achieve ideal transmission ratio, high driving torque, steady transimmison, main shaft long service life, brief structure, easy maintenance and low maintenance cost.

- The support sleeve of main shaft and main case is lined with brass bush to prevent occlusion and is easy to dissassembly.

- Ring die feed pellet mill adopts automatic grease adding system.

The purpose of feed material conditioning

- To promote the gelatinization of starch and protein modification, in order to improve the quality of feed pellets and increase the rate of return.

- Improve the efficiency of granulation (pelletizing).

- Kills Salmonella in feed.

Sample feed pellets

If you are not sure which feed pellet mill to choose for your feed pellet line, just send us a message, and you will get professional guidance!

Get In Touch