- Project Name: 1-2t/h chicken feed pellets line

- Built in: Uganda

- Year: 2016

- Main Raw Materials: maize, soybean, soybean oil meal, sunflower seed oil cakes, pre-mix compound, fish powder.

This 1-2t/h chicken feed pellets line was built in Uganda. The client had raw materials of maize, soybean, soybean oil meal, sunflower seed oil cakes, pre-mix compound and fish powder.

When producing chicken feed pellets, the particle material and powder material are fed into the feed mixer separately: particle materials are conveyed by the auger to the crusher for crushing, then enter feed mixer; while powder material is directly conveyed by auger to the mixer. By mixing for 2-3 minutes, the mixed material is elevated to storage bin, and delivered by speed-adjustable auger into the feed pellet mill conditioner. After fully mixed with steam inside the conditioner, the raw material is fed into feed pellet mill pelletizing chamber for making chicken feed pellets.

After pelletizing, the feed pellets have high moisture and temperature, so they must be cooled down to room temperature by pellet cooler. Then go through pellets sieving machine. The feed pellets that meet requirements will be packed by feed pellets packaging machine; those too large feed pellets will be crumbled into smaller particles by feed pellets crumbler, while power will go back for reproduction.

Receiving feed pellets

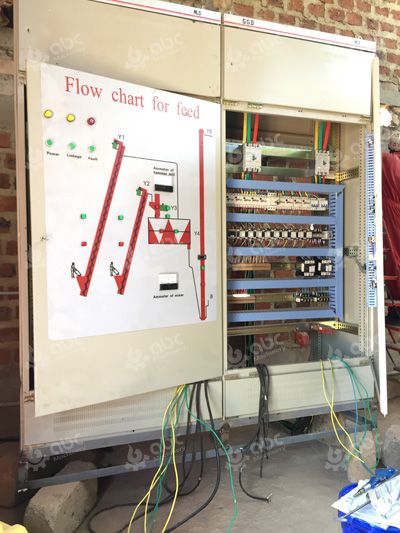

Electric control cabinet

Large chicken feed pellets

Small feed pellets for chicks

Highlights of this chicken feed pellets line

- The conditioner of this chicken feed pellets line uses digital frequency control to control feed pellet mill productivity.

- The crushing machine above mixing storage bin can run forward and backward, which greatly increases the utilization rate of the crushing machine hammers, and the machine does not need to be disassembled frequently for replacing hammers.

Venturing into chicken feed pellets line

A chicken feed pellets line is used for the production of chicken feeds in the form of pellets in masses usually several tons in an hour. The demand for chicken pellets is high because of the average consumption level of chicken.The process of chicken feed pellets line is discussed in the steps below

1. The crushing process

In this step, a hammer mill is used to grind or crush the raw material into different powder sizes depending on the specification in order to achieve optimal pellets for feeding chicken.

2. The mixing and blending process

Here different types of ingredients are added to the ground raw material, mixed and then blended to ensure there is uniformity in the ingredients and nutrients in each of the pellets that will be produced in the chicken feed pellets line.

3. Pellet milling process

The mill for processing pellets is the major component in the chicken feed pellets line. There are 2 different types of millers which are: the flat die pellet mill and ring die pellet mill. The ring dies pellet mill has higher production capacity as compared to the flat die pellet mill.

4. The cooling process

After pelleting of the crushed and blended ingredients, they have to be cooled since they come out of the pelleting mill at temperatures that are about 88℃ and high humidity content. This temperature has to be hastily reduced and balance the moisture content level at 12% in order to ensure the pellets can be stored and handled without issues. The pellets have to all be cooled equally and uniformly after the chicken feed pellets line process.

For making feed pellets for chicks, usually the produced feed pellets are crumbled into small particles. This method can increase feed pellets line production efficiency and reduce power consumption compared to directly manufaturing small diameter feed pellets.

5. The packaging process

In order to store the pellets according to desired quantities after they come out of the chicken feed pellets line, they have to be packed in bags and stored depending on each pellets needs. The packaging also ensures moisture content is maintained. The process of packaging is handled by a semi-automatic packaging machine which weighs the feeds, puts them in bags pneumatically and places them on a conveyer belt which has sewing machines to sew the top of the bags sealing them.

6. Pellet line control center

This is only for large scale feed pellets line. The chicken feed pellets line is sophisticated and each step needs to be controlled by an advanced computer system. The control center directs the grinding process, mixing and blending, pelleting process, the cooling process, packaging and sealing process on the conveyer belt. Each control center is preprogrammed according to the chicken feed pellets.

In order to have a successful chicken feed pellets line, you must have the infrastructural amenities such as a silo for storage of the raw and final products. In the USA for example, 90,000 tons of chicken feeds are consumed in 3 months which is a very high demand that needs to be met with a higher and consistent supply of the chicken feeds. This makes chicken feed pellets line a great investment. On the downside, the starting capital is high because the equipment and buildings are expensive plus the cost of suppliers. Expenditure too is high because of high electricity bills but on the brighter side, after settling, the profit obtained in the closing capital will be higher than the expenditure and injection into the business venture. Location is also important to consider when setting up the business. It is most likely to do well in the countryside and suburban areas where poultry farming is practiced. Setting up near the clients also reduces the expenditure on transportation.