Chickens grow and develop quickly, have a strong nutrient metabolism, a small digestive tract volume, as well as digestive function is not yet well developed, therefore, the requirements for feed nutrition are relatively high. We design chicken pellet feed formulas with appropriately high nutritional parameters, in the selection of raw materials to choose those nutrient-rich, easy to digest and absorb raw materials.

(Read More:poultry feed pellets processing technology)

800~1000Kg/h Chicken Feed Pellet Plant Business in Botswana

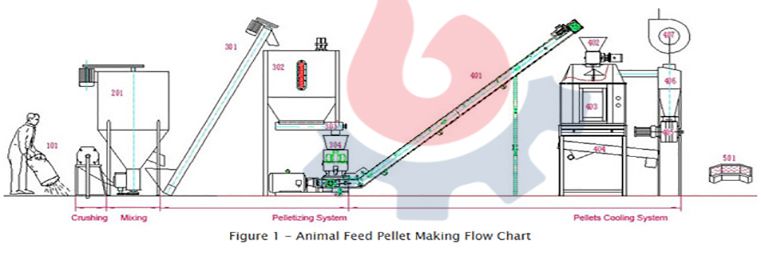

Recently, a customer planning to set up his own poultry feed farm in Botswana consulted ABC Machinery about the business plan and the required equipment and purchased a complete feed line of 800 ~1000 kg/h, including a grinder, mixer, pellet mill, cooler and two auxiliary units (conveyor and buffer bin). The simple process flow of chicken feed pellets is crushing → mixing → pelleting → cooling.This Bozwana customer aims to set up his own feed pellet mill, not only for his own use (farm), but also for sale (neighboring farmers).

Photos of 800~1000Kg/h Chicken Feed Pellet Plant Business in Botswana

What are the Significant Benefits of Pelleting in Poultry Feed Mills?

Pellets Making Process for Poultry

Poultry feed can be divided into different forms such as crushed, pounded and pellets. Feed form and feed size (fine, medium and coarse) have a significant impact on the growth, physical characteristics and digestive tract function of chickens. The pounded form usually leads to some waste due to the separation of grains from other components, while pelleted feeds overcome this problem by producing uniform proportions, making the feed into small, homogeneous particles that facilitate feeding and ensure a balanced intake of various nutrients by chickens.

-

Reduce contamination and improve feeding behavior of chickens

The use of poultry feed machines for pelleting reduces the waste of chicken feed and water contamination. In addition, the feeding behavior of chickens has improved. Poultry feed mill manufacturers these machines are designed in such a way that the volume of feed can be reduced by 15-18%. The form of chicken feed pellets succeeds in avoiding the pickiness of the animal in the feed, which leads to a more balanced intake of nutrients and increases the growth and productivity of chickens. In addition to the reduction of feed waste, the feed conversion rate is also appreciated.

-

In the poultry feed mill, the raw material will be ready for consumption during the pelletizing process.

This adds better flavor to the feed and also provides better digestibility, which will help chickens grow faster and stay healthy. It reduces salmonella (a bacterium found in the intestinal tract), mold, etc. The pelleting process does not allow growth inhibitors, such as cotton and trypsin.

-

The pelletizing process in poultry feed mills solves mixing difficulties, perfectly controls particle size and improves ingredient separation.

Suppliers and exporters of poultry feed mill machines help people in the poultry farming business to save 15-20% of the cost of chicken feed. Pelleting improves food efficiency by producing better nutrient density, enhancing the presence of vitamin E and B12, and increasing the digestibility and ME value of certain ingredients. As a result, it improves the performance of chickens. The following table is small-scale feed pellet production line for poultry and cattle.

| Model Power (Kw) | Capacity (kg/h) | Weight (kg) | Dimension (mm) | |

|---|---|---|---|---|

| STLP300 | 45.7 | 600-800 | 2464 | 15000*4000*4500 |

| STLP400 | 61.2 | 800-1000 | 2902 | 15000*4000*4500 |

The importance of pellet quality in poultry feed

The pelleting process consists of breaking the raw material by adding water and heat in the form of steam. The conditioned process then involves breaking down the raw material by adding heat in the form of water as well as steam. The conditioned feed ingredients are crushed into a dense substance and shaped. The heat and moisture in the ingredients are controlled with the help of cooling so that the ingredients can withstand moderately rough handling without causing unnecessary breakage. The pellets can then be crushed into smaller particles to allow chickens to consume the feed efficiently.

Manufacturers, suppliers and exporters involved in the provision of poultry feeding machines help customers to improve the quality and efficiency of chicken feed, thereby improving their behavior and performance. Poultry feed form is considered to have a significant impact on chicken intake and eventual growth. When producing broiler feed, the form of feed ingredients and feed particle size, require a great deal of attention.

Video of STLP300 / STLP400 Production Line Working