Make Nutrition-Balanced Feed Pellets for Pigs

In the pig breeding process, if it is a small-scale pig farm, the whole set of feeding is usually completed manually. However, if a pig farmer wants to further expand the breeding environment and breeding scale, he needs to purchase breeding equipment and know some knowledge about pig feed formula and purchases pig feed pellet machines.

ABC Machinery offers complete feed mill construction solutions with advanced technology, efficient equipment, professional installation, complete support and quality service. If you want to know some small details of pig feed, please click the button below to consult us!

The Benefits of Pig Feed Pellets

1. Less feed waste and less segregation of diet ingredients during feed handling. Feed pelletization helps to make it easier to process the feed and helps reduce feed waste. In addition, though making pig feed pellets can be costly, the benefits far outweigh the cost.

2. Better feed efficiency and greater starch digestibility. One of the benefits of making pig feed pellets is that it makes it easier to be able to handle pig feed and of course reduce wastage. What’s more, pig feed pellets greatly increase the nutrient digestibility. The reason being that the heat involved during the process of manufacturing pig feed pellets is able to break down carbohydrate bonds.This makes them become more digestible by pigs.

Pig Feed Pellets

Ingredients for making pig feed

For a Pig feed pellet machine to be able to make the feed pellets, there are various ingredients required and they include:

| Cereals | Sources include sorghum, rice bran, millet, and corn |

|---|---|

| Proteins and Fat | Sources include fishmeal, bone meal, rapeseed cake, soybean meal, and cottonseed cake |

| Additives | Including sweeteners, spices, vitamins, mineral elements, molasses, and fat |

Tips for making pig feed pellets

It is worth noting that the type and quantity of nutrient requirements required by pigs differ from one stage of growth to another. It is important therefore that you combine the right proportion of the ingredients or raw materials. It is important that when you buy a pig feed pellet machine that you are also supplied with pig feed pellet formulas.That is according to the various stages of pig growth. Consequently, here are some tips involved in regards to how to make pig feed pellets for you.

- Moisture content: Ensure that the moisture content of the raw materials for feed pellets is between 10%-12% after conditioning. A moisture content of between 16%-17 % is also just okay. The thing is that how dryer or wetter the raw materials are will have an effect on the finished pellets quality. You can dry the raw materials naturally in the sun or you can employ the use of a drier.

- Crushing of raw materials: You must crush the raw materials before you can start making pig feed pellet. That is important because if the sizes of the raw materials are relatively bigger then pressing them into pellets may not be easy.if you can manage to crush the raw materials into the finest powder or size then the better. This will make the pelletizing rate and the final quality of the finished pellets to be better.

- Conveying raw materials.Feeding the raw materials through the feeder into the Pig feed pellet machine. By doing that, the raw materials will be compressed to die's columned holes and subsequently discharged from the pig feed pellet machine.

- Cooling and storage: After processing of the pig feed pellets, they are often soft and hot. A cooling machine will help in taking away both the heat and moisture on the pig feed pellets surface. The result is dry and hard pellets that you can package for storage. This is generally how to make pig feed pellets.

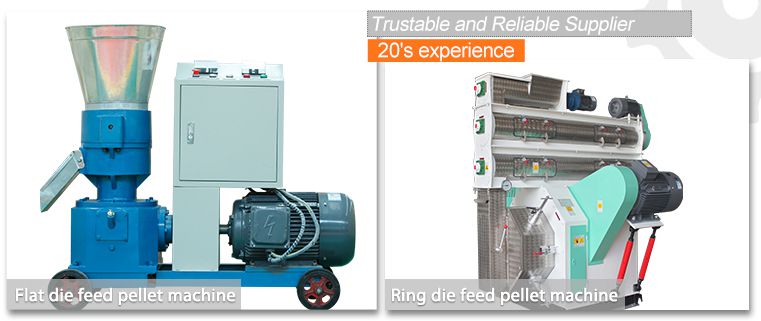

Pig Feed Pellet Machine for Sale

Of course for you to make the feed pellets, you will require the right pig feed pellet machine.There are not only small household feed pellet machines, but also large commercial feed pellet machines for you to choose from. Just tell us the scale and environment of your farm, and we will have professional people to help you answer your doubts, and provide you with some equipment details and cost suggestions.

Choose a proper pig feed pellet machine

When seeing the importance of the feed pellet machine, do you want to have a feed pellet machine suitable for your farm? There are a number of factors to consider.

- For example,some pellet machines can only process raw materials that are dry and therefore you will be disadvantaged if you want some moisturized raw materials included in the making of the pellets.

- Furthermore, the pellet machine must have die and rollers that are of high quality as that will guarantee quality pellets.

- Additionally, it is important that you choose a pellet machine that is easy to use and has spare parts readily available.