With the development of animal husbandry and animal feed manufacturing and processing in the world, the demand for forage grass is increasing day by day, but there are also higher requirements on the palatability, utilization rate, nutritional value, storage and processing of forage grass. Under this background, ordinary grass products (hay, bale, grass block, grass powder) are not able to meet market demand. Forage grass pellets that have good palatability and can effectively improve the utilization rate and digestibility of forage grasses are widely favored by the market, and will be the main development direction of future forage grass processing.

Forage Grass Pellet as Animal Feed

Benefits of Starting Forage Grass Pellet Making Business

Forage grass pellet is a kind of forage product which is formed by fully pulverized forage grass powder and added steam according to production requirements, fully mixed and pressed by forage grass pellet making machine. It has many advantages to feed animals with forage grass pellets:

- The nutritional ingredients of forage pellet feed are more diversified to meet the nutritional needs of more kinds of livestock animals.

- It can increase the intake of ruminant livestock and improve the digestibility of forage pellet feed.

- Reduce the intake time and reduce the physical energy consumption of livestock.

- Small volume, convenient for transportation and storage. Effective prevention of mildew; can effectively reduce the loss in transportation.

There are many benefits of starting a forage grass pellet making business for livestock. One of the worth mentioning benefits is that the raw material (forage grass) required to produce these pellets is available throughout the year. It means you can have easy access to the raw material and it is also available at a low cost. Having an easily accessible raw material can help you reduce feed pellet mill factory running cost and earn more than you invest in this business. (Read more: Small Cattle Feed Plant Cost >>)

Start Forage Grass Pellet Making Business

The animal feed pellet making machine used in this business are also low-cost machines. These grass pellet machines do not require much maintenance, consume less energy, and can be used to process other types of raw materials as well. Forage grass pellets are nutritious, easy to feed and transport. Due to these reasons, farmers are not getting more interested in grass pellets than the loose forage grass. As the use of forage grass is increasing, it has become a great business opportunity for investors to set up a complete pellet production line to produce high quality forage grass pellet for sales. You can invest less and earn more through this profitable business.

Forage Grass Pellets Processing Technology

Forage Grass Pellet Processing Machines

- Grass Moisture Controlling

The most critical step for forage grass pellets processing technology is to regulate the moisture content of raw materials. First, the water content of the raw material must be measured, and then the water should be added till the moisture content reaches the amount required for feed processing. The results showed that the optimum moisture content of legume forage was 14%-16%, and that of gramineous forage was 13%-15%. It is very important for the produced forage grass pellets for sale.

- Forage Grass Pelletizing and Cooling

In the process of forage grass production, forage grass pellet making machine is a key equipment. The forage powder is stirred and extruded during the rolling process. Under normal conditions, the temperature of the particles just coming out of the sieve hole is about 80℃. So they need to be cooled from high temperature to room temperature, the moisture content of the straw powder is generally reduced by 3% ~ 5%. Therefore, the moisture content of the forage grass pellets after cooling is less than 11% ~ 13%. As the water content is very low, it is suitable for long-term storage without moldy deterioration.

Setup Forage Grass Pellet Mill Plant

Forage pellets can be processed according to the nutritional requirements of various livestock and poultry to prepare grass granules with different nutritional components. The pellet size can be adjusted by the pellet making machine and processed according to requirements. If you are interested in setting up forage grass pellet mill plant and want to know the detailed equipment and project cost, just get in touch with us to get professional suggestion!

1~2TPH Forage Grass Pellet Making Machine for Sales

Forage Grass Pellet Making Machine

| Model | Capacity | Ring Die Inner Diameter | Feeder Power | Conditioner Motor Power | Dimension | Weight |

|---|---|---|---|---|---|---|

| BPM25 | 1~2 T/H | 250 mm | 0.75 kw | 1.1 kw | 1750× 650× 1750 mm | 800 kg |

Setup Complete Feed Mill Plant for Forage Grass Pellets Making

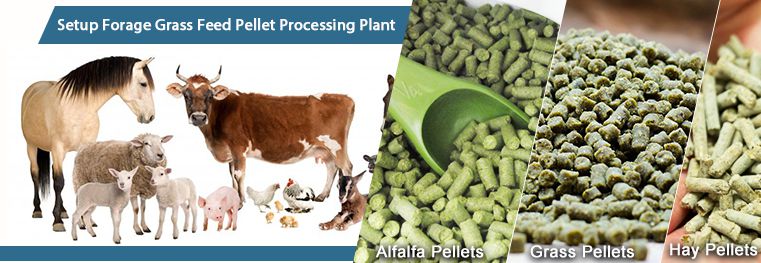

Setup forage grass feed pellet processing plant – factory price forage grass pellet making machine for feed manufacturing: buy forage grass pellet making machine from feed pellet mill manufacturer or supplier at factory price, get FREE technical instruction of forage grass pellet production process and business plan to set up forage grass feed pellet mill project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

Types of Forage Grass Pellets on Sale in the Market

Forage Grass Pellets Maded by Feed Mill

- Pure Grass Pellets

Such products are usually processed from a single variety of forage grass raw material into pellet feed, such as Leymus chinensis pellet feed, alfalfa pellet feed and so on. The advantages of this kind of products are single raw material, simple feed mill process, strong operability; but the shortcomings of pellet feed nutrients are limited by raw materials, cannot be diversified. (Related project: 2TPH Alfalfa Hay Feed Pellet Plant >>)

- Mixed Forage Grass Pellet Feed

This kind of pellet feed is based on two or more kinds of raw materials, which is produced by a suitable proportion, such as the mixed pellet feed of Leymus chinensis and concentrate feed, the mixed pellet feed of alfalfa and caragana, the mixed pellet feed of alfalfa and straw, etc. Their advantages are to diversify the nutrition of pellet feed. It can effectively utilize forage resources and solve an effective way of insufficient forage yield in some areas.

- Special Forage Pellet Feed

This kind of feed is produced according to the different nutritional requirements of different livestock and livestock at different stages of development. This kind of feed can make nutrition more perfect; livestock can absorb more easily and effectively improve the utilization of feed. This kind of special mixed feed is very popular in the market and will be the main direction of forage pellet feed development in the future. (Related project: 2~5TPH Cattle Feed Pellet Mill Setup Cost >>)

Forage grass pellet feed ingredients and effects

According to the experiment, lambs of 8 months old were fattened with mixed forage grass pellet feed for 50 days. The average daily gain was 190 grams, and the feed consumption was 6.4kg per kg of weight gain. Using forage grass pellet feed to produce fat lambs is a feasible way to promote the development of animal husbandry both in pastoral areas and in rural areas.