A well-designed Tailored Cattle Feed Pellet Formula is critical for optimizing cattle growth performance and feed conversion efficiency. Sorghum grain, as a cost-effective and nutrient-dense ingredient, has emerged as a viable alternative to corn in cattle feed production.

Tailored Cattle Feed Pellet Formula with Sorghum Grain

This article delves into the technical nuances of integrating sorghum grain for cattle feed pellets making into customized formulas, providing actionable engineering insights for factory investors and technical decision-makers.

Nutritional Advantages of Sorghum Grain in Cattle Pellets

Sorghum grain offers unique nutritional benefits that align with the demands of a Tailored Cattle Feed Pellet Formula. Its energy content ranges from 3,100 to 3,400 kcal/kg DM, comparable to corn’s 3,200 to 3,500 kcal/kg DM, making it a reliable energy source for ruminants.

Key Nutrient Composition

The table below compares sorghum grain’s nutritional profile with corn, highlighting its suitability for customized cattle feed:

| Nutrient (DM Basis) | Sorghum Grain | Corn | Cattle Requirement (Finishing Stage) |

|---|---|---|---|

|

Crude Protein (%) |

10.5–12.0 |

8.5–10.0 |

11–13% |

|

Starch (%) |

65–72 |

68–75 |

60–70% |

|

Neutral Detergent Fiber (%) |

12–15 |

10–12 |

14–18% |

|

Fat (%) |

2.5–3.5 |

3.0–4.0 |

2–4% |

|

Metabolizable Energy (kcal/kg) |

2,800–2,950 |

2,850–3,000 |

2,700–2,900 |

Stage-Specific Nutritional Adaptation

Different cattle production stages require targeted nutrient adjustments in the Tailored Cattle Feed Pellet Formula:

-

Growing Cattle (200–400 kg): Sorghum-based formulas should contain 12–13% crude protein and 3,000–3,100 kcal/kg ME to support daily gains of 1.2–1.5 kg.

-

Finishing Cattle (400–600 kg): Increase starch content to 68–70% (using sorghum’s high starch availability) and reduce protein to 11–12% to optimize feed conversion ratio (FCR) to 5.8–6.2:1.

-

Lactating Cows: Sorghum’s low rumen-degradable protein (35–40% of CP) helps maintain milk production at 28–32 kg/day while reducing nitrogen excretion by 15–20%.

Sorghum’s tannin content (0.5–2.0% DM) provides additional benefits: it reduces bloat risk by 30–40% in grazing cattle and improves protein utilization by slowing rumen fermentation. However, high-tannin sorghum (>1.5% DM) requires processing (e.g., steam flaking at 120–130°C for 2–3 minutes) to avoid reducing palatability.

When formulating a Tailored Cattle Feed Pellet Formula with sorghum, balancing energy, protein, and fiber is critical to leverage its nutritional advantages while mitigating anti-nutritional factors. Our engineering team specializes in customizing nutrient ratios based on regional sorghum quality and cattle production goals, ensuring optimal performance. Partner with us to develop a sorghum-integrated formula that aligns with your production targets and maximizes feed efficiency.

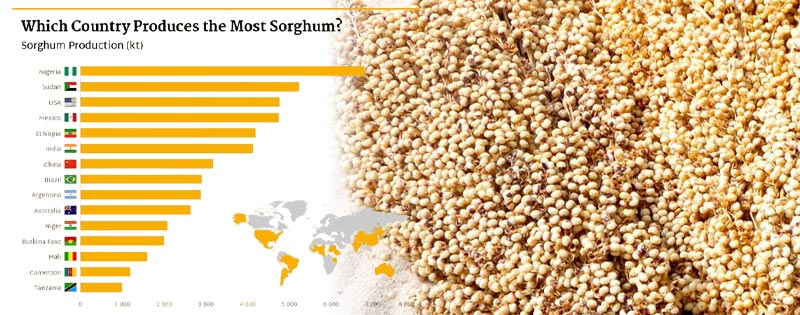

Regional Sourcing & Cost Benefits of Sorghum Feed

Sorghum’s global availability and cost competitiveness make it a strategic choice for Tailored Cattle Feed Pellet Formula projects. Regional production hubs influence raw material costs and supply chain efficiency, directly impacting project ROI.

Global Sorghum Sourcing for Cattle Feed Pellet Production

Major sorghum-producing regions include North America (35% of global production), Africa (28%), and Asia (22%), with average farmgate prices ranging from $200–$300/ton, compared to corn’s $250–$380/ton. This price difference translates to a 15–20% reduction in feed ingredient costs when substituting sorghum for corn in cattle feed formulas.

For example, in the United States, sorghum costs $220–$260/ton (2024 data) versus corn’s $280–$320/ton, resulting in $60–$80/ton savings in ingredient costs. In Brazil, sorghum’s price advantage is even more pronounced ($180–$220/ton vs. corn’s $240–$280/ton), making it a preferred choice for South American feed mills. These cost savings can increase project ROI by 8–12% over a 5-year production cycle.

Sorghum’s drought tolerance (requiring 30–40% less water than corn) ensures stable supply even in arid regions, reducing supply chain risks. For global investors, sourcing sorghum from local or regional producers minimizes transportation costs (typically $20–$40/ton for long-haul shipments) and supports sustainable production practices. Our team provides regional sorghum supply chain analysis and cost modeling to help you optimize raw material sourcing for your tailored cattle feed pellet project.

Sorghum Feed Pellet Line Equipment Configuration

A sorghum-specific production line requires equipment tailored to its physical properties. Key components include a hammer mill with 3–4 mm screens, a double-shaft mixer (mixing uniformity ≥95%), a steam conditioner (with variable temperature control), and a counterflow cooler (reducing pellet temperature to ≤10°C above ambient). Our sorghum feed pellet line solutions offer capacities ranging from 0.5–20 tons/hour with energy consumption as low as 65–75 kWh/ton. Contact us to configure a cost-effective equipment package for your tailored sorghum cattle feed pellet project.

Integrating sorghum grain delivers nutritional, cost, and processing advantages for cattle feed producers. From nutrient optimization and regional sourcing to equipment configuration, our engineering solutions address every aspect of sorghum-based feed pellet production.

By leveraging data-driven strategies and customized equipment, global investors and engineers can maximize project efficiency, reduce costs, and achieve superior cattle performance. Trust our expertise to turn your sorghum feed pellet vision into a high-performing, profitable reality with a Tailored Cattle Feed Pellet Formula that meets your unique production needs.