In New Zealand, a new company specializing in selling animal feed has invested in a mini cattle feed pellets production line with a capacity of 600-800kg/h. The main equipment, including crushing, mixing, pelleting, cooling, and packaging machines, is sourced from ABC Machinery, a manufacturer and distributor with decades of experience in feed production. (Read More: Commercial Animal Feed Produciton Plant at Facotry Price>> )

Small Scale Cattle Feed Manufacturing Plant

If you're interested in the cattle feed pellet business, contact us now! ABC Machinery is a professional supplier of cattle feed production lines and equipment, offering one-stop solutions. Whether you're looking for information on cattle feed pellet production lines, cattle feed production machines, formulas for making cattle feed, or advice on running a cattle feed business, we have experts in animal feed production who are ready to assist you!

Photos Display: A Small-scale Cattle Feed Pellets Processing Line Shipped to New Zealand

Cost-effective Mini Flat Die Feed Pellet Mills for Sale

Internal Details of Feed Pellet Machine for Cattle

Feed Pellet Manufacturing Mill Silo

Cooling Machine & Cyclone Dust Collector at Low Cost

Feed Pellets Conveyor

Cattle Feed Pellets Product Packing Machine

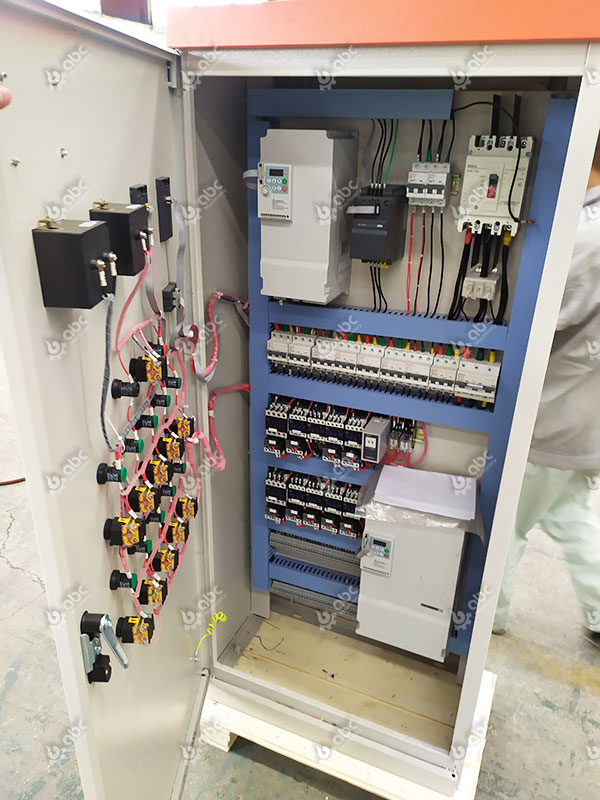

Cattle Feed Line Central Control Cabinet

Feed Pellet Line Control Cabinet Inside

With years of experience in cattle feed production, we provide high-quality, efficient cattle feed production equipment. Whether you need a mini cattle feed machine or a small cattle feed pellet unit, we offer competitive prices. Our equipment includes cattle feed grinders, corn grinders for cattle feed, cattle feed mixers, and more, catering to your various production requirements. Learn more animal feed pellet making equipment price and get free quotation, please feel free to contact us!

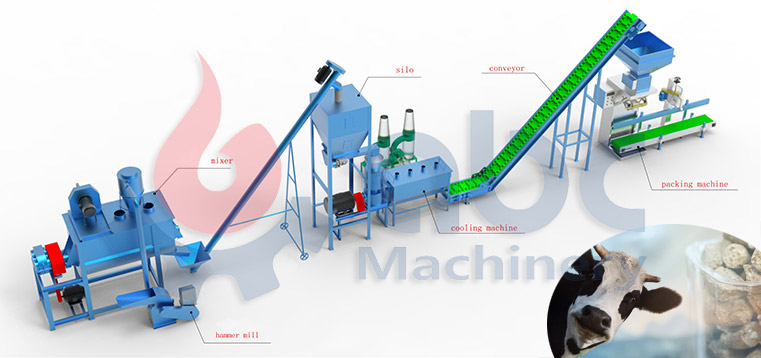

Process Flow of 600-800 Kg/h Cattle Feed Pellet Production Line

600-800kg/h Cattle Feed Pellet Mill Process Flowchart

Livestock feed pellets have become increasingly popular in New Zealand, driven by the growing demand for high-quality feed for various livestock, including cattle, sheep, and poultry. Making cattle feed pellets in New Zealand is a meticulous process that involves the use of specialized equipment and high-quality ingredients to ensure the nutritional needs of the animals are met, which includes the following key steps:

-

Formulating Cattle Feed Recipes:

The raw materials & formulation used in the production of livestock feed pellets in New Zealand are carefully selected to ensure they meet the nutritional requirements of the animals. Common ingredients include grains, protein sources (such as soybean meal), vitamins, and minerals.

| Ingredient | Proportion | Purpose |

|---|---|---|

| Corn | 45% - 55% | Provide energy |

| Soybean meal | 20% - 30% | Provide protein |

| Silage | 10% - 20% | Provide roughage |

| Minerals and vitamins | 1% - 2% | Maintain health |

| Salt | 0.5% - 1% | Maintain water balance and nerve function |

This is a basic example of a cattle feed formula. Actual formulas may vary depending on the breed of cow, stage of growth, and production goals.

-

Grinding and Mixing Process:

After careful selection, the raw materials are ground into a fine powder using specialized cattle feed grinders. Subsequently, the ground ingredients are thoroughly mixed to achieve a homogeneous distribution of essential nutrients, enhancing the overall nutritional value of the feed.

-

Feed Pelletizing Process: Nutrient-Rich Pellet Creation

The blended ingredients are then fed into flat-die feed pellet mills, where they are compressed under high pressure into small, cylindrical pellets. This process not only ensures uniform pellet size but also improves the feed's digestibility and palatability, promoting optimal health and milk production in cow.(Latest News: 2-3 TPH Chicken Feed Pellet Mill Built in New Zealand >>)

-

Cooling and Drying Process: Quality Preservation

Following the pelletizing process, the freshly formed pellets are hot and moist. To enhance their shelf life and preserve their quality, the pellets undergo cooling and drying using advanced pellet coolers and dryers. This critical step reduces moisture content, preventing spoilage, and maintaining the feed's nutritional integrity.

-

Screening and Packaging Process: Quality Assurance

Once cooled and dried, the pellets are meticulously screened to remove any fines or dust particles, ensuring a high-quality end beef or dairy product. Finally, the pellets are carefully packaged in bags or bulk containers, ready for distribution to livestock farms across New Zealand, providing a consistent and reliable source of nutritious feed for livestock.

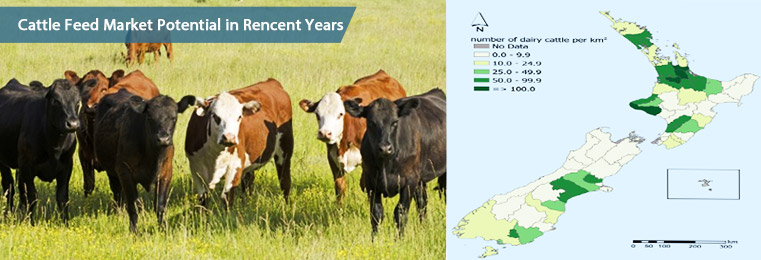

New Zealand Animal Feed Pellet Processing Market for Cattle Sheep Poultry

New Zealand boasts abundant high-quality agricultural raw materials, such as premium grains, pastures, and top-notch protein sources, providing a solid foundation for producing high-quality livestock feed. Additionally, its agriculture is primarily dominated by the livestock sector, particularly renowned for dairy products and wool. Consequently, the livestock feed pellet market is primarily influenced by sectors like dairy cattle and sheep farming.

New Zealand Animal Feed Pellet Processing Market

Emerging Cattle Feed Pellets Investment Potential New Zealand

The cattle feed pellet market in New Zealand is witnessing steady growth, propelled by the increasing demand for high-quality feed products. This growth is further fueled by farmers' growing recognition of the advantages of using pellets over traditional feed forms like mash or crumbles.

-

A key trend in this market is the adoption of specialized feed pellets customized to meet the specific nutritional requirements of cattle. There is a rising demand for pellets enriched with higher protein content for poultry feed and those fortified with essential vitamins and minerals for cows.

-

Another emerging trend is the utilization of alternative ingredients, including locally sourced grains and by-products from the food industry. This practice aims to reduce production costs and enhance the sustainability of feed production.

Starting Your Own Cattle Feed Pellet Making Business

For those interested in initiating their cost-effective cattle feed pellet production plant in New Zealand, it's crucial to develop a comprehensive business plan outlining the feed pellet production process, target market, and marketing strategy. Additionally, investing in the right equipment such as pellet mills, grinders, mixers, and coolers is essential. Ensuring compliance with local regulations and quality standards is also paramount.(related article: How to Make an Animal Feed Pellets Plant Buisness Plan>>)

With a well-structured business plan, securing funding for your cattle feed pellet plant business becomes more attainable. Our affordable and comprehensive cattle feed production plans help you save money and avoid costly mistakes.

Contact us with your requirements, and our team of project engineers will guide you through the process. Check out our feed pellet project ptoposal guides for reference:

In addition to equipment supply, ABC Machinery also offer services such as cattle feed plant layout design and guidance on the cattle feed manufacturing process. Our goal is to help you succeed in the cattle feed business and achieve your commercial objectives. Contact us now for more information on the cattle feed pellet business, and we'll be happy to help you!