5TPH Animal Feed Pellet Making Machine to Indonesia

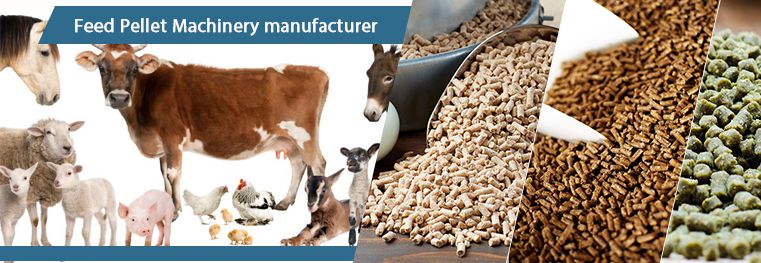

As the demand for meat, eggs, and milk in countries around the world continues to increase with economic development and population growth, the animal husbandry industry will continue to develop by leaps and bounds. Therefore, the overall demand for feed is increasing. As the main body of feed, the market capacity of compound feed will continue to grow in the long term.

Our animal feed processing solutions can help you save energy and raw materials, and produce high-quality feed. As a technology partner with long-term experience in this industry, we support you in all aspects of producing reliable animal feed.

5TPH Animal Feed Pellet Making Machine to Indonesia Project Report

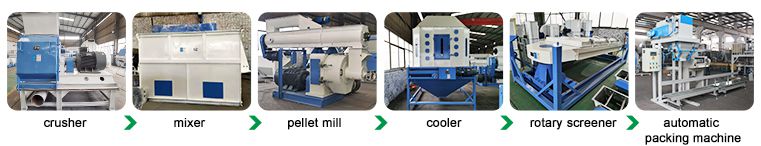

Recently, an Indonesian customer contacted us. He is an animal feed manufacturer and wanted to buy an animal feed production line to provide feed pellets to local farmers. The raw materials he has are grass and grains, and we recommended him a 5TPH feed pellet ring die set. The main equipment is crusher, mixer, ring die granulator, and packaging machine.

Animal Feed Pellet Machine Process

5TPH of Feed Pellet Plant Process Flow

This complete set of ring die feed pellets has a designed total production capacity of 5-10T/H for animal pellets. Firstly, feed materials from the feeding port into the production line. The raw materials that need to be crushed are fed from the pellet feed port to the crusher in batches, and then the crusher is fed by a screw conveyor. Directly enter the pelletizing section for pelletizing and cooling processing, and finally the baler will pack the finished feed pellets.

The whole set of feed pellets adopts splicing frames, with compact design, reasonable structure, meeting environmental protection requirements, and directional design according to customer requirements.

| Project Name | Location |

|---|---|

| 2-4TPH Animal Feed Manufacturing Plant for Cattle and Poultry | Uzbekistan |

| STLP300 Cow Feed Pellet Plant | South Africa |

| 1-2T/H Chicken Feed Pellets Line | Uganda |

Animal Feed Pellet Making Machine Video

If you are interested in our equipment and need more details and a quotation list, don't hesitate to contact us ! You can get a quick reply in one business day! We are here to help you !

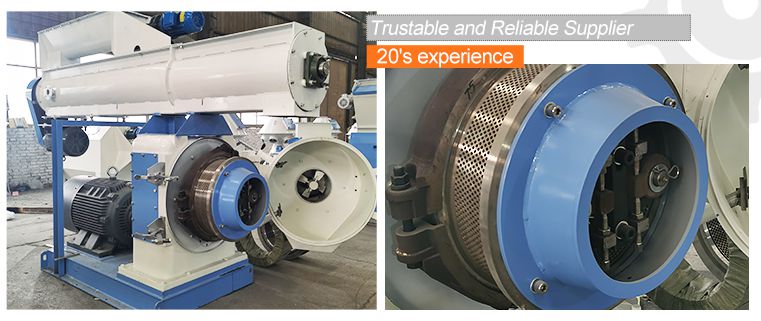

Daily Maintenance of Feed Ring Die Pellet Machine

The feed pellet making machine is the core equipment in animal feed production. It not only affects production efficiency, but also has a great impact on feed quality.Therefore, it is necessary to strengthen the inspection and maintenance of animal feed ring die pellet machine to ensure the normal operation of the pellet machine.So in the actual factory production, what are the precautions for the daily maintenance of the feed ring die pellet machine?

Feed Ring Die Pellet Machine for Sale

-

1. Frequently clean the floating dust and dirt on the surface of the pellet machine. Lubricating oil is added regularly, and lubricating oil is filled in the oil injection mark on the shafts of the two pressure rollers before production to ensure that the machine is working in a good lubrication state.

-

2. Regularly check the easily worn parts such as ring die, pressure roller, cutting blade, mixing blade, belt pulley, and timely adjustment or replacement to ensure the normal and effective operation of the pellet machine.

-

3. Frequently adjust the gap between the ring die and the pressure roller. If the machine is blocked, the pressure roller must be loosened, the inner wall material of the ring die must be removed and the die roller gap must be readjusted.

-

4. Use high-quality ring molds and pressure rollers. Eliminate the use of inferior ring dies with out-of-round and rough inner holes, and choose the compression ratio of the ring dies according to different formulas to ensure smooth output of the ring dies, avoid increasing power consumption and reducing productivity.

-

5. Put an end to overload production. During the production process, the working capacity of the pellet itself should not be exceeded, otherwise motor damage and accelerated wear of components will occur, which will shorten the service life of the pellets.

Before using the machine, you need to read and fully understand the operation requirements of the system. To start using it, the first thing is to check the operations manual. If you are interested in the ring die feed pellet machine, whether you are using it at home or on a farm, we can provide the most suitable animal feed pellet making machine according to your actual needs and budget !