Poultry feed milling, as a core segment, requires meticulous planning—from the layout of the feed milling plant to the refinement of the feed mill process. A well-designed regional division minimizes operational bottlenecks, while optimized feed processing flow ensures consistent feed quality and maximizes output.

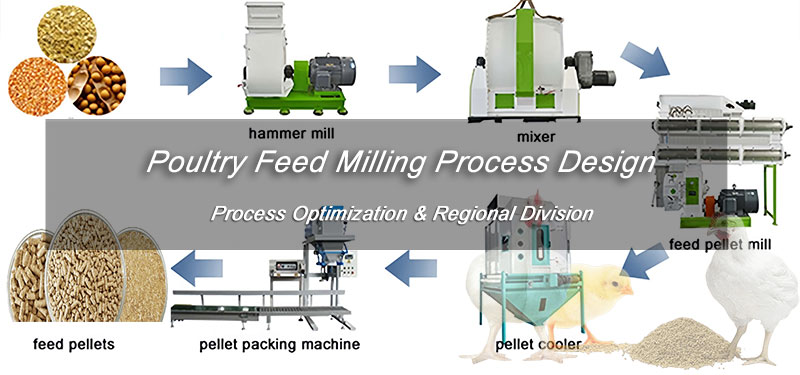

Step-by-Step Poultry Feed Production Flow

This guide delves into the key strategies for structuring feed milling plants and enhancing poultry feed milling processes, integrating essential tools like feed milling machines.

Scientific Regional Division of Feed Milling Plants: The Foundation of Efficient Operations

Poultry Feed Mill Functional Zone Layout: Efficient Flow Design

A feed milling plant’s regional layout is not merely a spatial arrangement but a strategic framework that streamlines material flow, reduces labor costs, and mitigates contamination risks. To achieve this, the plant should be divided into functional zones based on the sequence of the feed processing flow, with clear boundaries and logistical connections.

-

Raw Material Storage Zone:

This zone serves as the entry point for grains, protein sources, and additives. It must be designed with moisture-proof and pest-control features to preserve raw material quality.

By the way, proximity to the raw material pretreatment zone is essential to minimize transportation time, as long-distance movement can increase material waste and labor intensity.

-

Pretreatment Zone:

Equipped with preliminary cleaning equipment (e.g., sieves, magnetic separators), this zone removes impurities like stones and metals that could damage feed milling machines. Integrating animal feed milling equipment here, such as crushers for coarse grinding, prepares raw materials for fine processing.

-

Processing Zone:

The heart of the feed milling plant, this zone houses key feed milling machines, including poultry feed milling machines, chicken feed milling machines, and mixing equipment. To optimize efficiency, machines should be arranged in a linear sequence that follows the feed milling process: crushing → batching → mixing → granulation.

-

Finished Product Storage and Packaging Zone:

This zone should be isolated from the raw material and processing zones to prevent cross-contamination. It includes silos for bulk storage and packaging lines for bagged products. Designing this zone with easy access to loading docks ensures quick distribution, a key factor in meeting the demands of the feed milling industry.

-

Auxiliary Zones:

These include quality control labs, maintenance rooms, and staff facilities.

Key Principles for Zone Design

-

Regional division must prioritize “flow efficiency” and “safety.” For instance, hazardous areas (e.g., zones with high-dust equipment) should be equipped with ventilation systems to protect workers and prevent fire risks.

-

Additionally, the layout should accommodate future expansion. Common in the growing feed milling industry by leaving space for adding more feed milling machines or expanding storage capacity.

By aligning zone design with the natural progression of the feed processing flow, a feed milling plant can reduce material handling time by 30% or more, laying the groundwork for optimized production. Contact us now for a free consultation to get a poultry feed pellet plant layout and design!

How to Optimize the Production Process of Poultry Feed Pellets?

The poultry feed milling process is a multi-step journey that transforms raw materials into nutritionally balanced pellets. Each stage—from crushing to packaging—offers opportunities for optimization, leveraging advanced feed milling equipment and data-driven adjustments to boost output and reduce waste.

-

Crushing Stage:

The goal here is to achieve uniform particle size, which directly impacts the efficiency of mixing and granulation. Using a specialized poultry feed milling machine with adjustable screens allows producers to control particle size (typically 1–2 mm for poultry feed).

Compared to a generic animal feed milling machine, a poultry-specific model reduces energy consumption by 15–20% and ensures consistent grinding.

-

Batching and Mixing Stage:

Precision is key in this stage, as inaccurate ingredient ratios can compromise feed nutrition. Integrating automated batching systems with high-precision scales minimizes human error, ensuring that additives (e.g., vitamins, minerals) are mixed evenly. The mixing time should be optimized based on the feed formula—for example, 3–5 minutes for compound feeds—to avoid over-mixing (which wastes energy) or under-mixing (which causes nutrient inconsistencies).

Using a horizontal mixer, a common type of feed milling equipment, making it ideal for large-scale poultry feed production.

-

Pelleting Stage:

This stage converts mixed powder into pellets, improving feed palatability and reducing transportation waste. The granulator, a core feed milling machine, requires parameter adjustments to optimize pellet hardness and density. For poultry feed, a die hole diameter of 3–4 mm and a temperature of 80–90°C are optimal—these settings ensure pellets are durable enough to withstand handling but easy for poultry to digest.

Post-granulation, the cooling stage is equally important: using a counter-flow cooler reduces pellet temperature from 80°C to room temperature in 10–15 minutes, preventing moisture buildup and mold growth.

-

Screening and Packaging Stage:

After cooling, pellets are screened to remove fine particles (which can be recycled back to the mixing stage) using a vibrating screen. This step improves product uniformity and reduces waste. The packaging stage should use automated systems that adjust bag weight based on customer needs (e.g., 25 kg for small farms, 1 ton for large operations).

Advanced feed processing techniques, especially digital solutions like computer-aided formula design, boost poultry feed production efficiency. They ensure the process matches the nutritional needs of different poultry stages (e.g., broilers vs. layers) and effectively improves farmers’ feed conversion rates.

ABC Machinery Part of successful Feed Production Cases Show

1-2TPH feed pellet plant in Uganda, 2-4TPH feed pellet line in Uzbekistan, 1TPH feed mill in Kuwait, and 0.6-1TPH small plants in the South Africa—ABC Machinery’s poultry feed plants are top picks for global clients (business or farm use). Each includes essential equipment for quality and efficiency. Contact us directly for detailed machine prices and project parameters!

Knowledge Hubs: Comparison of Different Animal Feed Production Processes

|

Feed Type |

Key Differences from Poultry Feed |

Key Processes/Equipment |

|---|---|---|

|

Chicken Feed |

Requires stricter control over protein content (18–22% for broilers) and particle size (0.8–1.5 mm) to suit chicks’ digestive systems. |

Specialized chicken feed milling machines, precision grinding process |

|

Fish Feed |

Relies heavily on extrusion process (especially for floating fish feed); needs to ensure pellet stability in water and feed intake rate. |

Extruders (a type of feed milling equipment), high-temperature and high-pressure pelleting process, lipid coating process |

|

Cattle Feed |

Has high crude fiber content; processes are designed around fiber digestion needs. |

Hay grinding process, silage preparation process, large-scale automated feed milling plants |

While poultry feed milling has unique requirements, insights from other animal feed production processes—such as fish, cattle, and chicken feed—can inform optimization strategies. Comparing different feed milling processes highlights opportunities to adapt technologies and workflows for better results.

Poultry feed milling success hinges on two pillars: scientific regional division of feed milling plants and optimized feed mill processes. A well-designed plant layout minimizes waste and streamlines workflows, while refining each stage of the poultry feed production process—using specialized feed milling machines like poultry feed milling machines and chicken feed milling machines—ensures quality and efficiency.

Whether you’re scaling an existing feed milling plant or building a new one, prioritizing these strategies will not only meet current market demands but also position your operation for long-term growth.